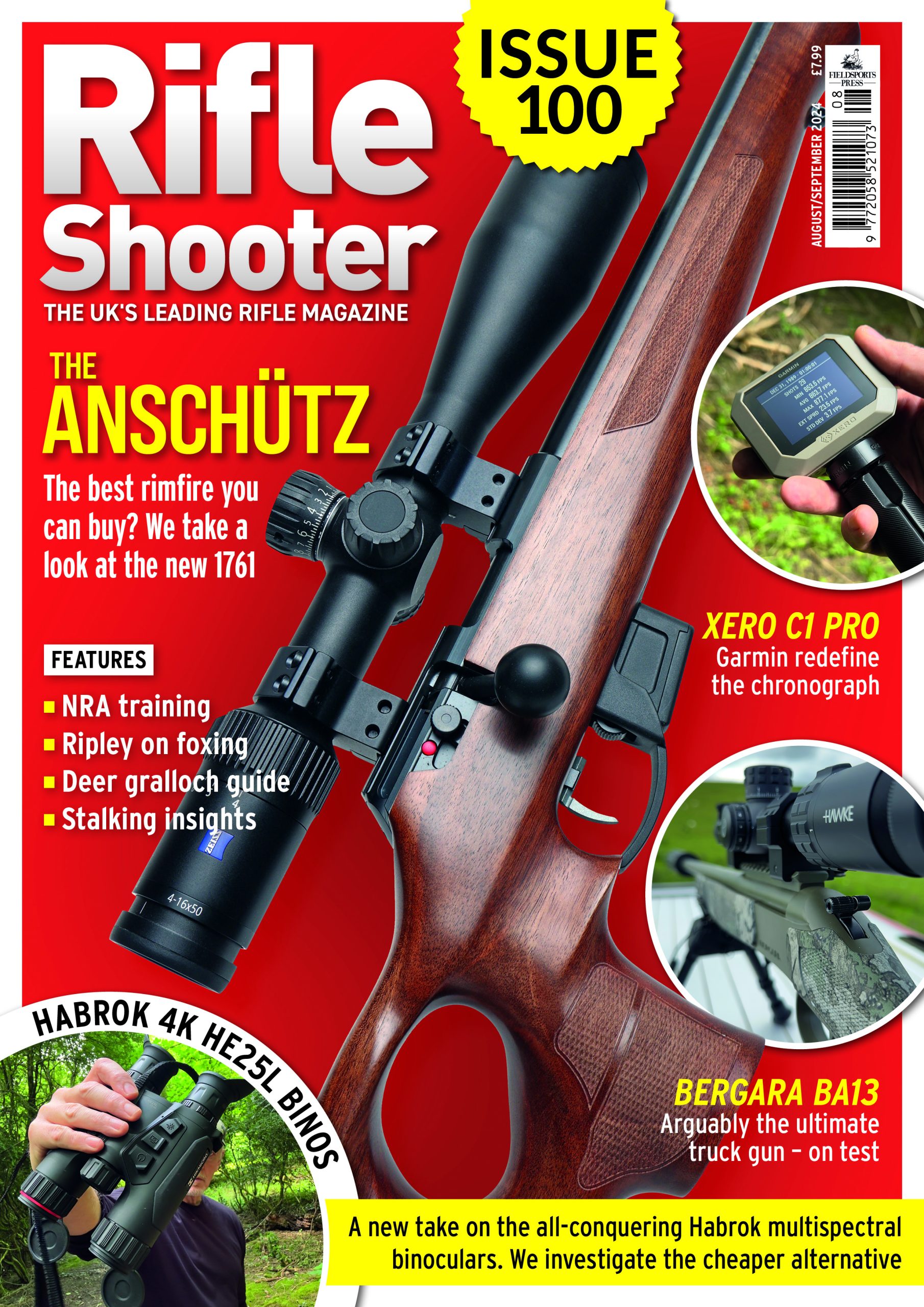

Mauser M12 Impact in .308 Win – in depth test and review

Chris Parkin puts the Mauser M12 Impact in .308 Win to the test… and struggles to find fault!

PROS

Fantastic action and trigger

Superb recoil characteristics form the stock’s ergonomics

Fit and finish quality are unquestionable

Versatile ammunition preferences with handloads shining even brighter

CONS

No left hander

OPINION

I don’t like reviewing M12s because I find them hard to find fault, on either a technical or a personal level. They say you should fear a man with one gun, and an M12 owner will still have a decent wad of cash in his pocket after he has bought his. A very competent rifle.

TECH SPECS

Calibre: 308 on test (22-250, 243, 6.5×55, 270, 7×64, 30-06, 8×57, 9.3×62 also available plus magnums)

Weight: 3.56kg/7.8lbs

Barrel length: 22” (560mm) (7mm Rem Mag, 300 WinMag and 338 WM have 24” / 610mm barrel)

Twist rate: 1-11”/279mm

Overall Length: 1069mm/42”

Magazine capacity: 5+1 (4+1 in magnums)

Trigger: Single stage, 925gr/2lbs

Length of Pull: 359 mm/14 1/8”

Scope mounting: Drilled and tapped for any M98 compatible bases

Warranty: 10 years

Spares available: Larger Synthetic bolt handle, Magazines, Manual Cocker, Forend stud and stock spacers

PRICE

Mauser M12 Max in 308 Winchester

£1515

Mauser Hexalock Scope rings and bases

£135

CONTACT

0207 6222116

ALSO USED

Minox ZX5i 3-15×56 SF Riflescope

MINOX, 01494 481004

Tier-One Spartan III Sound Moderator

01924 404313

AMMO USED

Lapua 150gr Soft Point ammunition

Viking Arms

01423 780810

Fiocchi 150gr SST ammunition

Edgar Brothers

01625 613177

Winchester 150gr Extreme Point ammunition

Browning UK

01235 514550

Sierra Bullets and PPU ammunition

Henry Krank & Co.

0113 256 9163

Vihtavouri Reloading powders and Lapua Cartridge Brass

Hannams Reloading

01977 681639

IN DEPTH REVIEW

I must come clean – I own an M12, and, given my picky nature, I feel I must be able to defend my choices with the greatest objectivity and respect for its peers. The M12 has been around for four years now and seems to have lived a quiet life in the UK. I haven’t seen many around in either walnut or synthetic furniture, and scratched my head as to why. There is no doubt that the design and manufacturing, specifically the shared barrel lineage with Blaser and Sauer, show very similar capability on target. Mauser seems to have been the black sheep of the family and, in my own head-to-head decision between the very similar Sauer 101 and the M12, I found the M12 to win by a very narrow margin, mainly because of the wing safety and very subtle, yet important, handling characteristics to the bolt.

This M12’s hammer forged barrel shows a 15x1mm thread at the crown with the slickest of execution. The crown – like all finishing on the 22” black tube from the 17.2mm muzzle back to the 28mm reinforce – is faultless. Everything ends up at 35mm where it press-fits into the action. Internal borescope inspection shows up nothing of concern, and a very sharp crown at the muzzle. Good hammer forging is hard to beat, and I see plenty of new ‘buttoned’ barrels with unsightly, if un-troublesome, machining marks internally. Hammered barrels coming from these machines, on any brand they are made for, seem to shoot well, clean easily and last a long time. They are, to put it somewhat incorrectly, ‘hard as nails’, but the empirical results cannot be argued with on paper or for longevity. The chamber sits ahead of the six-bolt lugs’ locking abutments that are set in two rows of three around the circumference of the 20mm bolt shaft. Twin lateral ports vent gas direct to the atmosphere in the event of a case rupture. The uniform cylindrical bolt with recessed lugs, rather than twin protruding lugs running along raceways down the action, is a guaranteed way to make a gun ‘run’ and cycle faster. A single groove runs along the lower surface to prevent rotation, fitting over the bolt stop-pin that is disengaged with a sprung button to the left rear side of the action. This M12 is a fast turn-bolt bolt gun in my hands because of the subtleties of the bolt handle. Exacting clearances and the way the bolt cams open and closed with forceful primary extraction seem to require so little effort on the 60-degree lift. A single claw extractor at two o’clock in the face of the upper right lug wrenches each fired case free of the chamber walls with perfect timing, and when the bolt draws rearwards, two plunger ejectors fling them forcefully from the action for a ‘belt and braces’ approach. The bolt handle extends 42mm from the outer surface of the shaft with a 20mm steel ball end to it. It sits perpendicular to the longitudinal axis of the bolt and projects straight out from the gun at 90 degrees laterally when open. Now, compare this with a 101 which has identical bolt lugs/cams, etc. yet a slightly different handle, and you’ll find it slower, especially for smaller or less muscular hands that will need leverage on some occasions. Longer handles generally run slower; they may be more ‘tacticool’ but, even on this long action with a 113mm stroke length, the longer handle applies a bit too much torque to the shaft longitudinally, risking a stuttering jam (it is also a slightly longer arc for your hand to rise through when cycling the gun). It’s very hard to describe this effect but easy to demonstrate.

The M12, above any other turn-bolt action rifle I have yet used, has everything in ideal proportion in my opinion. Straight pulls may be inherently faster without any ‘turning’ to do, but if the bolt hits your nose each time, you soon begin to automatically lift your head from the stock – is that faster? Perhaps, but is it better? Probably not when trying to reload and watch your bullet all the way into the quarry while trying to fight against a natural muscular reflex.

This M12 has two threaded holes in each action bridge for scope mounting. They will take anything in the ‘98 family’, from swing-offs to Picatinny rails, but this gun was supplied with Mauser’s new Hexalock mounts. Their compact radiused/triangular steel ‘male’ stubs slot into corresponding ‘females’ in the base of each 30mm scope ring. A small serrated lever to the side locks it in place. It’s a relatively giant version of the inbuilt system on the M03; it is equally functional but at a far more modest cost. The two levers turn 60 degrees backwards around the base of each ring and the scope lifts off. Slot it back on, push the levers forward and hey presto! Return to zero was within 2cm of my aim point at 100m. My only concern would be catching the levers on undergrowth or a branch, but I haven’t so far. Were I to do so, it would be immediately visually obvious anyway.

Wing safeties might look bulky, but with cold hands and gloves they are the masters of silent finger/thumb operation. This serrated lever locks the bolt closed when rearward; centre position sets the gun to safe with bolt unlocked; and forward enables fire. Both ‘SRS’ safe positions lock the firing pin, and cycling the bolt with this firing pin locked on the mid stage allows you to discern just how slick the lug mechanics of the action are without the firing pin spring confusing the tactile feel of the forces you are encountering. I also like the wing safeties’ subtle benefit. The firer is forced to remove their trigger finger from the blade to operate one quietly. Having lazy finger-weight on the trigger blade when disengaging thumb safeties must be one of the most common reasons for a negligent discharge. The trigger has an ultra-crisp single-stage pull of 950g/2lbs, with an 8mm-wide, deeply curved and smooth blade to sit on the finger pad at an ideal distance from the stock’s grip. I have yet to experience a disappointing trigger on any Blaser, Mauser M03/M12 or Sauer 100/101, and when you are teaching people to shoot a reliable trigger with crisp feel and 2-3lbs weighting is of great assistance. Shooters learn to time the progressive squeeze onto the blade, while they concentrate on aiming, so much more reliably. It looks to be weight adjustable, with a grub screw on the pristine machining of the mechanism, although Mauser do not advertise it as so and I left it well alone. This one felt as if it came in a little lighter than my own 950g M12 at first, but when weighed it still gave me 925g. This goes to show that with correct technique, and triggers this good, their precision allows you to notice such delicacy. You can feel the cocked action indicator protruding from the rear of the bolt’s shroud in the dark, and it’s also ringed in red for daytime visibility.

Five rounds will top-load into the staggered-column polymer magazine, either out of the gun or through the spacious open-topped action, when installed. Transit into the chamber via twin ramps runs quietly and smoothly from a gentle push-feed bolt face (propelled at any speed) that’s also capable of cycling rounds dropped straight onto the follower. These mags are tough and spring gently out of the gun into your palm from their flush fit. A recessed release catch is sited just forward in the bottom metal of the gun. The trigger guard is spacious for a gloved finger, and shows two 4mm Allen-headed M6 bolts at either end to retain the action into the recoil lug at the front, and the tang’s radiused tip.

My only reservation with the polymer stocks on the Extreme and Impact version of the M12 is slight flexibility in the slim fore-end (although, they are good synthetics for dampening both direct recoil force and resonant ‘ring’ transmitting to your head via your cheekbone). I do like the feel of walnut in both these respects, but not its fragility in the field. The Max’s laminate thumbhole seeks to give a third option of both aesthetic appeal and great ergonomics, with toughness and durability both physical and climatic. Laminates are a bit denser than walnut and, being very hard and stiff, don’t dampen the noise/vibration transmitted or the recoil felt like walnut. This one is very good, though, because it has retained all Mauser’s characterful design tweaks, such as the angled curves around the magazine well that can be seen all the way back to the earliest 98s. I have used, modified and built guns on a lot of laminate stocks, most of which are made of the same birch ply laminates in the very same factory. The finish and grain structure of Mauser’s laminate looks slightly different, and I think it feels a little softer in recoil and resonance, but this is a very subjective thought. Let us not forget that laminates appeared during the Second World War, so Mauser are not exactly new to this material which was seen on 98Ks. It blends seamlessly with modern thumbhole specification. The bi-tonal dark-brown colour is appealing to look at and thoroughly sealed against water ingress. It carries panels of sharply cut chequering at grip and fore-end, which remains heavy enough in profile to keep a firm yet relaxed grip on, without spoiling the sporter looks. The barrel floats fully in all circumstances and cannot be blamed for any wandering zero. I tested the bedding stress of this rifle with my usual bolt torque technique, and for a factory-made gun, it is good. The recoil lug fits into a steel-faced pocket in the stock with a tubular pillar around the rear action screw, so when you tighten to a specific torque it remains set solidly. Slacken the rear bolt and the action remains stationary without the barrel lifting out of the fore-end. It’s not hard to get right in a CNC-machined laminate with precise dimensions from the similarly manufactured steel of the gun, but it is amazing how many guns exhibit a badly done job. Small plastic pegs fit either side of the recoil lug to shim its centrality within the stock’s inlet, but unsurprisingly, mine had ‘no.1s’ symmetrically on both sides, indicating this stock to be stiffer and straighter than the similarly shimmed synthetic and walnut models. Laminates are machined from blanks that are already dried, glued and cured, so won’t warp or change after machining or any further strife through life once sealed.

The grip shows a minimal ambidextrous palm swell for hand-filling comfort. Glove manufacturers think my hands are ‘large’ in size and about perfect for this thumbhole cut out, but there is space for larger mitts. Reach to the trigger is ideal, yet more subtle ergonomics shine through. The very top of the grip to the rear of the trigger guard is unnecessarily chequered for flowing looks, yet deliberately slimmed to keep a gap between the timber and your trigger finger so that, as you squeeze, you don’t apply lateral pressure for those mythical ‘pulled’ shots. Likewise, the upper supporting bridge between rifle and comb has remained slender to enable a thumb-up position on the stock, if you prefer it in a fast-fire situation (I certainly do!). Length of pull is 359mm, or 141/8”, with no cast. A Monte Carlo cheekpiece rises 8mm above the parallel top of the stock. The firing pin sear on the underside of the bolt runs just 2mm above this, so Mauser have done a great job of keeping everything as ‘high and tight’ as possible. It’s a well thought-out job with no missed opportunities and, just to note, I accidentally spilled barrel cleaning solvent on the cheekpiece and didn’t notice for several days. It’s fierce stuff and had run down like a teardrop but wiped off 99% clean. I admit I was careless, but to be fair, mistakes are what damage guns and prove how durable they are. Some laminates absorb atmospheric moisture like a sponge, so I think Mauser deserves another mark for such a tough job; you won’t feel the stock swell fluffily after leaving the Max stood in moist leaf litter or rested on a damp straw bale.

Studs are fitted on the fore-end tip and underneath the butt for sling mounting; being of slightly smaller hole diameter, Mauser have included two swivels with the gun. I’d have liked a bipod stud under the fore-end, as this gun in a .243 or .22-250 would make a superb precision varminter. Fitting one is a five-minute job that I think further production guns will feature… I put one on myself as the stock was already prepared with an appropriate locating recess in the barrel channel. The fore-end deserves a bipod because it’s stiff and shoots well in all positions.

It’s hard to say that this is just an accurate gun, because most guns will shoot three- and five-round groups on paper with care, but not with impunity when hurried. The M12s just do it so easily. I will automatically disregard scopes, mounts and finally defective ammunition before I doubt the actions and barrels. The gun shot everything I put through it sub 25mm for three rounds at 100m. It showed little weight preference but I steer towards 150s in general for a good combination of speed and energy from sporting rifles. This 22” (560mm) tube was probably quite tight, generating good velocities well up into the 2,850fps (868 m/s) region. The cases showed acceptable but firm pressure signs. Nothing worrisome and the primary extraction of fired brass was never a problem with an action this refined. Most importantly, the recoil feel was surprising. Guns in .308, especially with 180gr bullets, can be lively and therefore show up handling character fast. The gun, or more specifically the stock, is heavier than the synthetic but it really drives in a straight line to the shoulder with minimal muzzle jump and sideways skip. I assumed the moderator was doing all of this, but shooting without it on really revealed how pleasant the gun was ‘naked’. Sierra, Lapua, Vihtavuori handload recipes became a little better still with three-round groups performing into the magical ¼” territory at 100m, but not every time. More importantly, the first cold-bore shot was always spot on the money with handloads and slightly better than factory, where more variance shows from box to box. Ten rounds did show the groups open up, but mean point of impact never shifted from a thermally stable barrel.

I will never agree to a thumbhole stock being faster than a regular grip, simply because you must make more movements to disengage the hand from the gun, operate the bolt, and then re-engage with the gun. The thumbhole and vertical pistol gripped gun holds snugly into your shoulder, seemingly with less effort needed. I set out to not like this Max… I don’t like laminates, yet the Max won me over and became yet another Mauser I tried hard to discredit and failed to do so on all grounds except personal preference. It balances well with a moderator, shoulders smoothly with a firm but absorbent and grippy recoil pad (seamlessly blended to the timber!), has a great trigger, bolt and barrel, and looks modest yet refined too.

Well, I’d maybe slim down the profile of the cheekpiece a bit for my cheeks, oh yes, and add that bipod stud, but that is it. I remember as a young man reading a book about the history of Africa and reading how a bunch of farmers outwitted and outshot the British Empire’s finest soldiers with the help of something called a ‘Mauser’. I think these early memories have really stuck with me as, regardless of the hundreds of guns I have shot, I specifically remember the first time I handled a 98, the first time I borrowed and shot an M03, and the first gun I ever picked up at the IWA trade show in Germany in 2013 – the freshly launched M12. I can use and appreciate most guns for positive and negative aspects of their character, but one fact remains – the M12 still stands out to me in the current market as a fine rifle, the only one I have ever described with that most closely held superlative. The Max continues this heritage without doubt because all the tiny details have a huge cumulative benefit.

Related Articles

Get the latest news delivered direct to your door

Subscribe to Rifle Shooter

Elevate your shooting experience with a subscription to Rifle Shooter magazine, the UK’s premier publication for dedicated rifle enthusiasts.

Whether you’re a seasoned shot or new to the sport, Rifle Shooter delivers expert insights, in-depth gear reviews and invaluable techniques to enhance your skills. Each bi-monthly issue brings you the latest in deer stalking, foxing, long-range shooting, and international hunting adventures, all crafted by leading experts from Britain and around the world.

By subscribing, you’ll not only save on the retail price but also gain exclusive access to £2 million Public Liability Insurance, covering recreational and professional use of shotguns, rifles, and airguns.

Don’t miss out on the opportunity to join a community of passionate shooters and stay at the forefront of rifle technology and technique.