Your pellet choice can affect the shot cycle on a springer, affecting both the felt recoil and the rifle’s muzzle energy; here, contributor Jim delves deep into the subject...

credit: Archant

credit: Archant

In this article, I am going to look at the shot cycle of a springer when shooting two pellets of similar weight, but of different composition and design, and their effect on the shot cycle, the recoil, and the perceived recoil. Before getting to the meat of the article, I think it worth explaining the history of our growing understanding of how the spring/piston airgun works, which will take us back to the late 1970s.

credit: Archant

credit: Archant

Gerald Cardew

A little over 40 years ago, the late, great Gerald Cardew published the most influential book in the long history of the spring air rifle (The Airgun from Trigger to Muzzle), and it turned practically everything people thought they knew about the workings of the springer on its head. Gerald’s background was in engineering, and he had a good knowledge of physics in general, and the branch of physics called ‘Mechanics’, which deals with motion and force, in particular, and he was probably the first person to use hard science in a serious attempt to unravel the secrets of the airgun.

credit: Archant

credit: Archant

Measuring momentum

Gerald’s starting point – and trump card – was devising a reliable means of measuring muzzle energy, or more precisely, pellet momentum, which he did by building his ballistic sledge and ballistic pendulum, both of which he later sold under his CARD trademark. The sledge and pendulum both worked by firing a pellet at a weight, either resting on a rail or hanging on the end of a pendulum, measuring the deflection – which was a measure of pellet momentum – then from that, calculating the pellet kinetic energy. Nowadays, we tend to take electronic chronoscopes for granted, but at the time of Gerald’s ballistic sledge and pendulum, being able to measure and calculate muzzle energy was nothing less than ground-breaking.

credit: Archant

credit: Archant

Power madness

The accepted ways of judging the ‘power’ of an airgun at the time were either to measure how many pages a pellet penetrated of an old telephone directory or mail order catalogue, or by a subjective appraisal of the recoil, and the fiercer the recoil, the greater the ‘power’ was believed to be. Both were utterly useless as measures of muzzle energy, of course, and the recoil appraisal method supported the widely held belief that the sure way to increase ‘power’ was to fit a beefier mainspring, and Gerald disproving that misconception with his ballistic sledge or pendulum was probably the greatest revelation of all time as far as the workings of the springer is concerned.

Despite Gerald unquestionably being the leading authority on the mechanics of the springer, he did not quite fully unravel the mysteries of the shot cycle, but as is normal in science, someone later built upon his work, and that someone was Professor Emeritus Mike Wright.

credit: Archant

credit: Archant

Diesel

Gerald’s work was based on experiments with springers that had fairly short piston strokes, and this led him to believe that all springers needed a degree of diesel assistance to achieve muzzle energies near our 12 ft.lb. limit. Despite almost everyone involved in springer tuning at the time buying into this theory, and lavishly lubricating springers to fuel dieseling, I did not, because I had modified springers so that they could achieve the limit without dieseling. Neither did Mike Wright, whose department of engineering and applied science at Aston University later carried out experiments under laboratory conditions to prove conclusively that not all springers needed diesel assistance; what they needed was more stroke.

It was Mike who recognised that the pellet gained most of its energy during the period that it and the piston were traveling in the same direction, that short strokes reduced this time, and that the only way a short stroke could increase the time was to get the pellet moving earlier in the stroke, by creating a pressure spike, courtesy of dieseling.

credit: Archant

credit: Archant

Cylinder pulse

Mike christened the period that the piston and pellet were travelling in the same direction as the ‘cylinder pulse’, and in order to understand it further, we needed to know when, in terms of piston travel, pellets started to move. Some people, me included, had a stab at finding start pressure by manually pushing a pellet and measuring the force needed to get it moving; if a .177 pellet needed five pounds of force (5 lbf) to get it moving, that equated to 205psi of air pressure (force divided by area), which would be achieved at roughly 85% of the available stroke. Mike approached the question by connecting his air cylinder to a barrel and measuring as best he could the pressure reading when the pellet moved, and came up with 25-27 bar (360-400psi) nearer 90% of the available stroke. Neither method of trying to determine start pressure gave us the precision we needed.

credit: Archant

credit: Archant

Peak pressure

It was not until 2015 that I hit upon a way of precisely controlling cylinder peak pressure in my .177 HW77, which was to fit cylinders of varying length and with varying bores inside the HW77’s compression cylinder, and using enough spring to ensure that the piston seal hit the insert at the end of the compression stroke, allowing me to calculate peak pressure from start and end volumes. I published details of the experiment and the test result in the August 2015 edition of Airgun World.

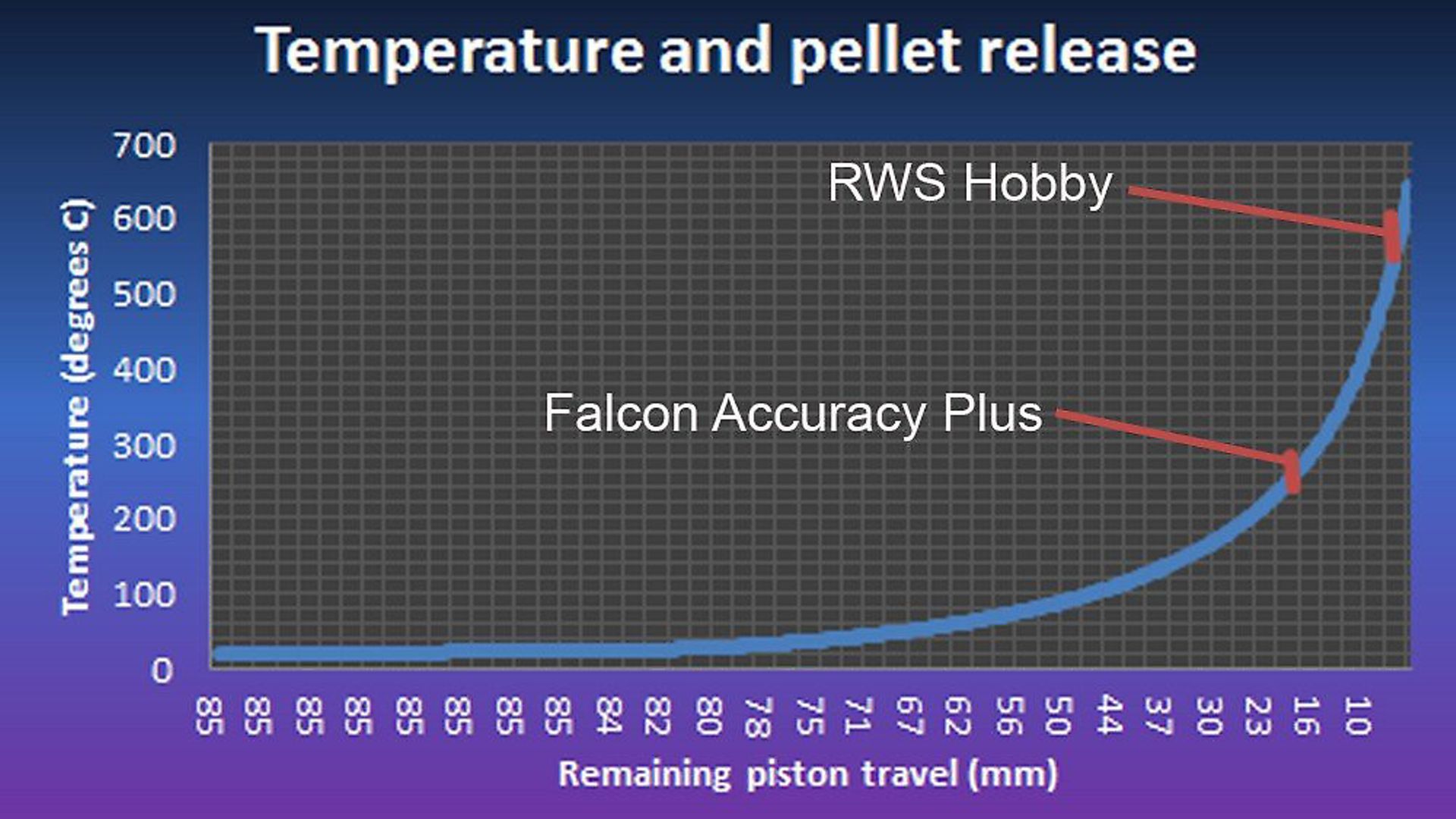

The start pressures depended on a combination of the malleability of the pellet – how hard or soft it was – and the thickness of the skirt. Soft, thin skirt pellets typically manufactured by JSB had the lowest start pressures, and harder pellets with thicker skirts had the highest, and the pressures for .177 pellets ranged from 120psi, roughly 78% into the stroke, to over 600psi – nearer 93% into the stroke.

credit: Archant

credit: Archant

Lows and Highs

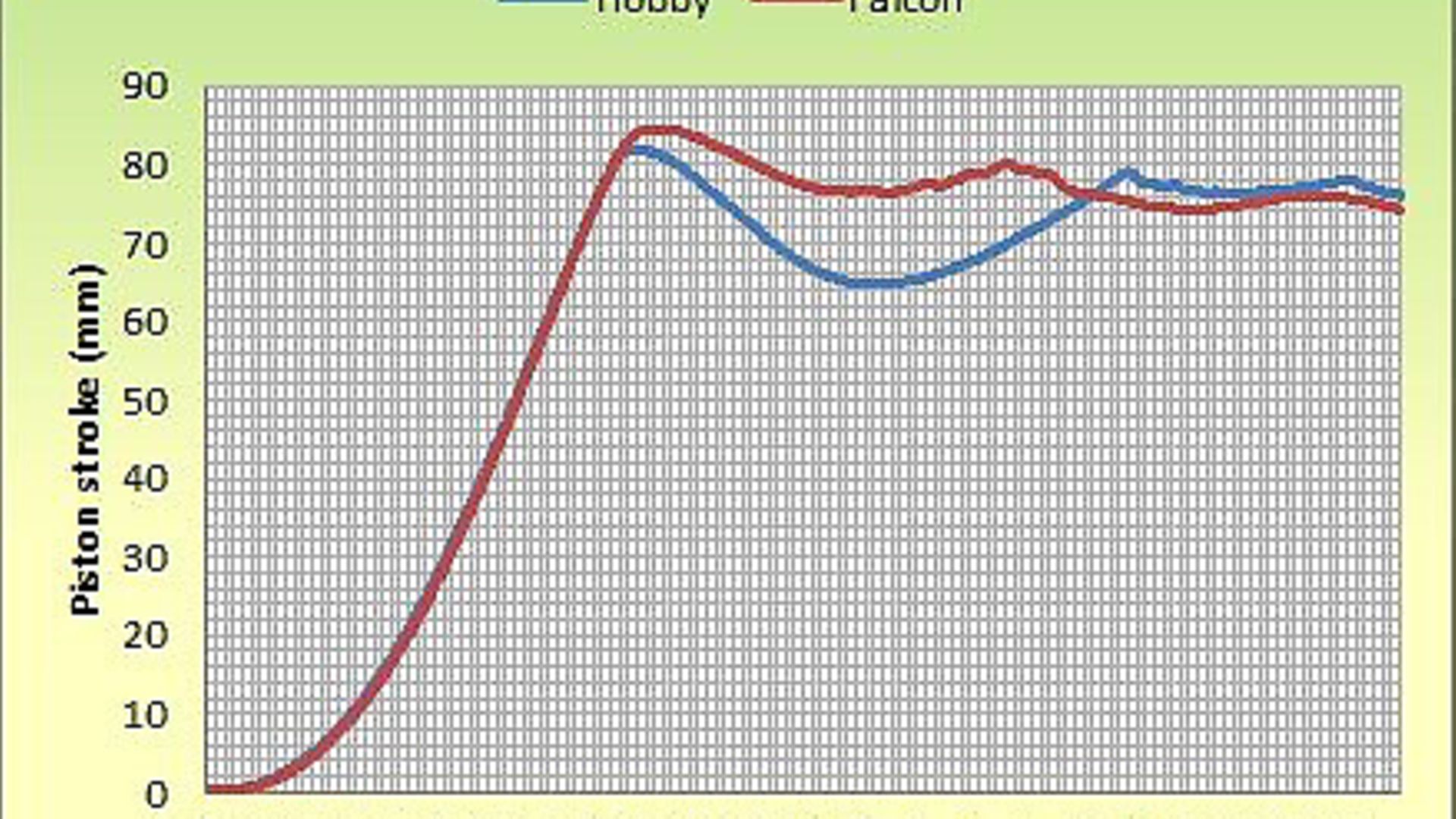

In a .177 rifle with 85mm of potential piston stroke, the lowest start pressure pellet – the Falcon Accuracy Plus –had a potential 18.7mm of cylinder pulse; the highest start pressure pellet of roughly comparable weight – RWS Hobby – had a meagre potential 5.95mm, less than a third as much, so given the importance of the cylinder pulse in determining muzzle energy, will the Falcon give massively higher muzzle energy?

The answer is no. In my TX200 with 85mm of piston stroke, I recorded Falcon Accuracy Plus muzzle energy of 10.82 ft.lbs., against Hobby muzzle energy of 10.03 ft.lbs., which suggests that the cylinder pulse, whilst a significant factor in determining muzzle energy, is not the only factor, and in fact, something else must be at work that compensates for the short cylinder pulse. That ‘something’ is obviously the higher cylinder pressure when the Hobby finally decides to let go.

credit: Archant

credit: Archant

Internal Energy

The Hobby might let go late in the piston stroke, but it has a force of 14.59 lbf acting on it, against the Falcon’s 2.91 lbf, and perhaps predictably, its initial acceleration in the barrel is blistering in comparison with the Falcon’s. Whilst the respective forces acting on the pellet explains why the muzzle energies can be not dissimilar with wildly differing cylinder pulses, there is another measure of the capability of the air to perform work on the pellet, and that is its internal kinetic energy.

The internal kinetic energy of air does not in itself do anything, but is a measure of the ability of a moving mass of air molecules to perform work, such as accelerating a pellet up a barrel. In my TX200, by the time the Falcon pellet starts to move, a little over 4 ft.lbs. has been added to the air’s internal kinetic energy through compression, rising to nearer 9.5 ft.lbs. when the Hobby lets go. The interesting thing about the internal kinetic energy is that we have a measure of it, and it is temperature. At the point of pellet start, the air temperature with the Hobby is 300ºC higher than with the Falcon.

The shot cycle

The Falcon and the Hobby represent the lowest and highest start pressure pellets within their weight category, so if we look at the shot cycles, all other pellets of even vaguely similar weight will come somewhere between them.

The earlier start of the Falcon means that for any given piston position between that point and the start of the Hobby, the cylinder pressure is lower, and so the piston travels further; in fact, a millimetre beyond the point of piston bounce with the Hobby, so the cylinder pulse not only starts earlier than that of the Hobby, but also carries on after the Hobby’s pulse has finished.

At piston bounce, the peak cylinder air pressure and temperature with the Falcon are much lower, so whilst the higher pressure of the air in front of the Hobby forces the piston into a quick reversal of direction, with the Falcon, the piston remains near enough to the cylinder end wall to provide pellet driving pressure that bit longer, so thanks to a combination of longer cylinder pulse and extended pellet driving pressure, it’s more energy efficient.

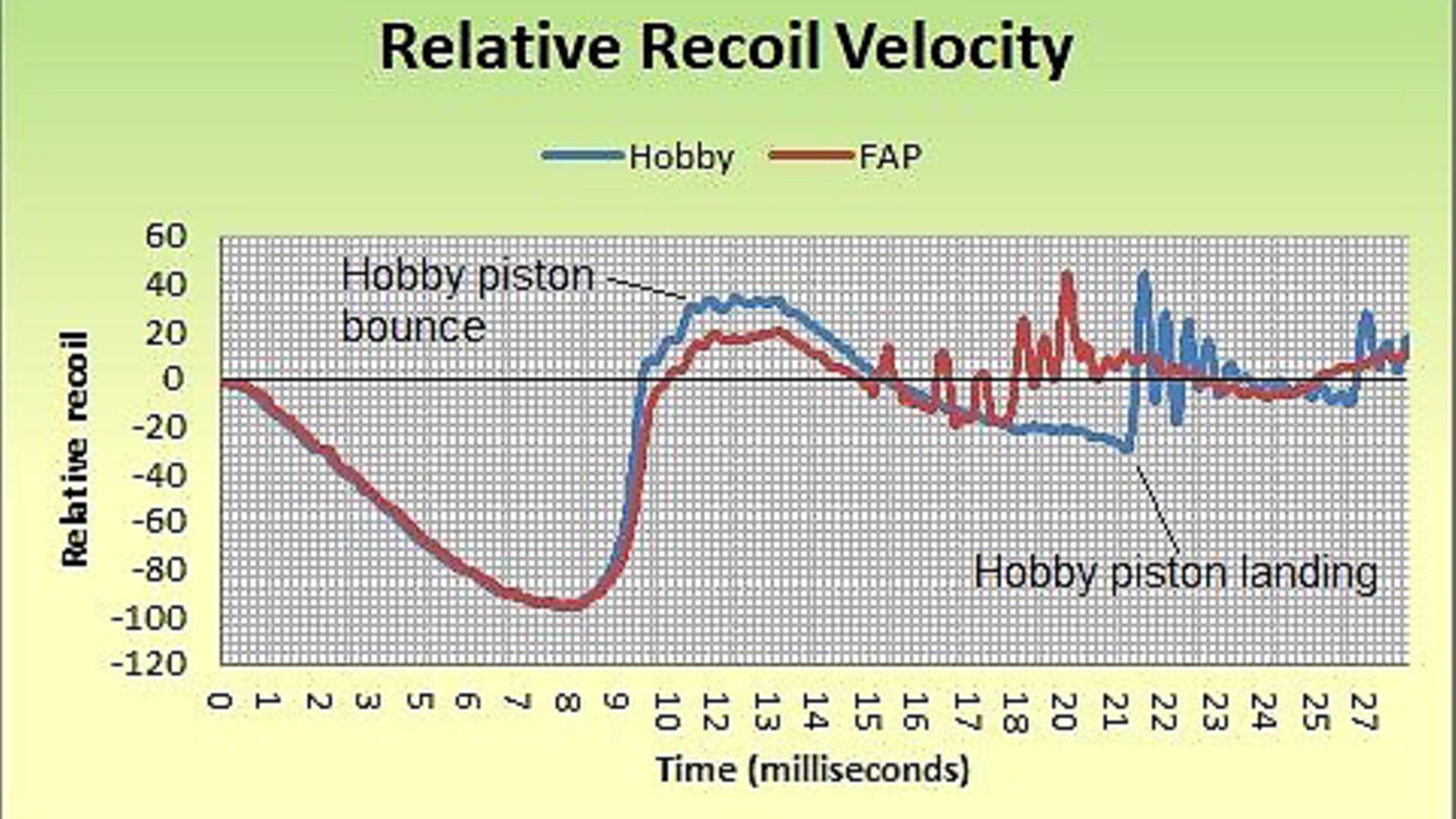

On the retreat

The higher cylinder air pressure with the Hobby causes the piston to retreat faster and further than with the Falcon, which means faster and further recoil surge, and it’s easy to see that it is the 0.8 ft.lb. difference in muzzle energy of the two pellets that’s driving it.

The differences in shot cycle obviously have a direct bearing on the felt recoil, but not necessarily in the way we might expect. The primary rearward recoil travel will be greater with the Falcon, but the difference will be so slight, at a fraction over 1%, that the user simply won’t be aware of it. What we might be aware of is the result of the greater forward surge with the Hobby, and possibly a harsher eventual piston landing, both of which will probably be apparent only as slightly increased sight picture disruption.

Diesel

There is only one way I know of, for certain, that the Hobby can match, let alone exceed, the muzzle energy of the Falcon in my TX200, and that is if autoignition and combustion sufficient to advance the Hobby’s start point occurs early in the compression stroke, and that’s exactly what was happening in the dieseling springers of Gerald Cardew’s day.

The base oil typically used in cylinder lubricants gives off fumes that autoignite at a little over 200ºC, which will occur when the piston is around 71-75% into the stroke, earlier than even the Falcon release point. That means that in my 85mm TX200, a dieseling shot with a Hobby would have up to a potential 21mm of cylinder pulse, which in conjunction with the light (6.9gn) weight of the pellet, would probably make it the most energy efficient pellet; the Number One to use for checking that a dieseling rifle was safely legal.

Couple of caveats

However, there are a couple of caveats, in that I am not aware of research to prove whether autoignition of typical cylinder lubricant occurs at 200ºC when the temperature is rising as quickly though the ‘flash point’, the temperature at which it gives off combustible fumes, and the autoignition point as it does in the springer, nor of any research into the flame propagation speed when autoignition does occur. The only thing that’s certain is that autoignition gets the Hobby moving earlier in the shot cycle, and the upshot is that its muzzle energy can exceed that of the Falcon.

Diesel or oversprung?

There seems to be a school of thought that if a high start pressure pellet gives higher muzzle energy than a low start pressure pellet, the rifle is believed to be ‘oversprung’. Whether the term oversprung refers to a higher rate (stiffer) spring pushing the piston nearer to the cylinder end and increasing peak air pressure, or to a spring with very high preload force to push the piston slightly less far, but keep it near the cylinder end to accelerate the pellet for longer, or a combination of these, is unclear. Whether the theory behind over-springing is correct is also unclear.

Deliberate dieseling

Following experiments in which I deliberately set my HW77 to diesel, and recorded the high start pressure RWS 8.3gn Superdome giving higher muzzle energy than the low start pressure JSB 8.4gn pellet purely as a consequence of the dieseling, I am satisfied that dieseling can advance the start point of the harder pellet sufficient to reverse the relative muzzle energies of the two pellets used in the test. The graph “Dieseling and non-dieseling HW77” shows the results of another experiment in which I compared the rifle short-stroked to 70mm and dieseling with the rifle at the full 81mm of stroke, and not dieseling, and it’s difficult to conclude other than dieseling, rather than over-springing, was the cause of the Hobby muzzle energy eclipsing the Falcon’s. The oversprung theory needs to be tested, to ensure that it is the spring, and not dieseling caused by the higher cylinder pressure that’s responsible, should hard pellets give higher muzzle energy.

Conclusion

Your choice of pellet has a significant effect on the shot cycle of the springer, affecting not only the feel of the recoil, but also the fundamental way in which the rifle creates its muzzle energy.